Glass and mirror machining. Drilling, countersinking and milling holes. Working on curved, shaped and straight edges. Chamfering of glass and mirrors.

All glass products undergo some processing before they reach the consumer. Glass edging, chamfering and drilling are the main types of processing.

Today's market demands high productivity and at the same time the highest quality of machining, which can only be achieved with highly reliable machines. In pursuit of this productivity and quality objective, Losk has installed state-of-the-art Bovone machines, where the variable speed has absolutely no effect on the constant quality.

In the summer of 2020, Intermac will commission the latest in its class, a multi-functional vertical CNC machining centre, the Vertmax 2.2.

The Vertmax 2.2 - 3.3 vertical machining centre is a complete high performance solution for glass processing in an automatic production process. It is ideal for the production of doors, partitions, facades and structural glazing.

The Vertmax 2.2 - 3.3 CNC machining centre is designed to perform the following operations:

- double-sided drilling

- milling

- grinding

- polishing

- countersinking

The finish quality is high and consistent!

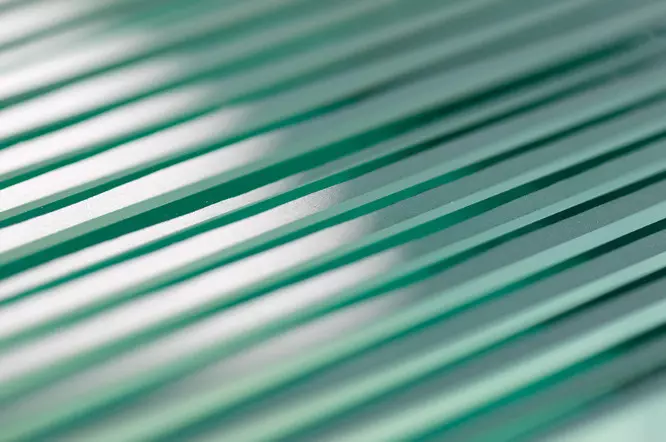

Straight edge processing of glass and mirrors

Straight-line glass processing (grinding, polishing) is carried out on Bovone machines: ELB 102, ELB 10/45 and the brand new ELB 12HS.

Bovone machines are considered the best in their class and allow the production of a perfect shiny edge surface (bevel) for both ordinary and laminated glass.

The commissioning of a new Bovone ELB 12HS machine and the reconfiguration of the conveyor system in LOSK's glass processing plant has significantly increased the productivity of the straight-line glass processing line.

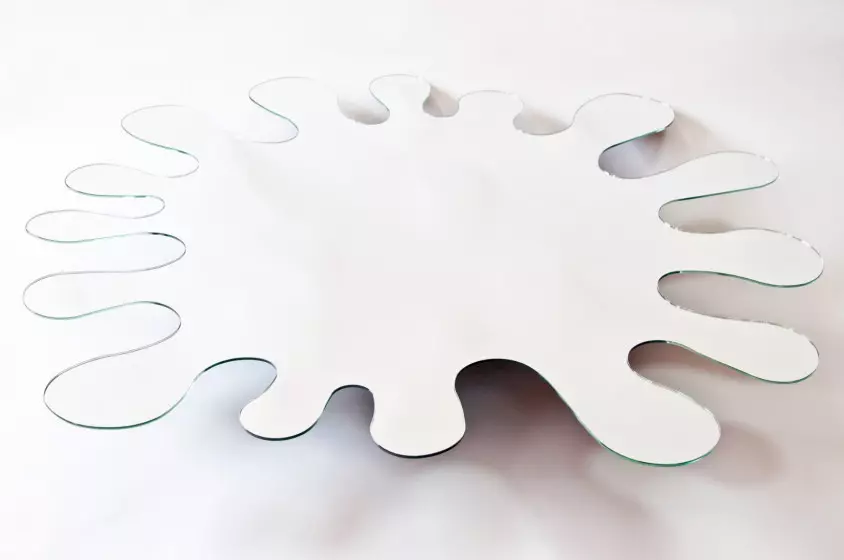

Treatment of curved edges on glass and mirrors

For complex types of glass and mirror processing, LOSK specialists use the new high-tech Intermac Master 43 Glass+ multifunctional centre.

"The Intermac Master 43 Glass Plus represents the latest evolution of INTERMAC products in the world of 3-axis glass machining centres.

Curved edges of glass and mirrors are also processed on Lovati LOV-1000-EES, Meccanica CAMBI and Z.Bavelloni SB-10 semi-automatic edge banding machines.

Facet on glass, mirror

The production of rectilinear bevels, currently up to 60mm wide, on glass and mirrors is carried out on a new high performance Bovone Model 471 machine.

Semi-automatic edging machines such as Lovati LOV-1000-EES, Meccanica CAMBI and Z.Bavelloni SB-10 are used to produce curved bevels on glass of various thicknesses.

For more complex types of glass processing, the high-tech multifunctional centre Intermac Master 43 Glass+ is used.

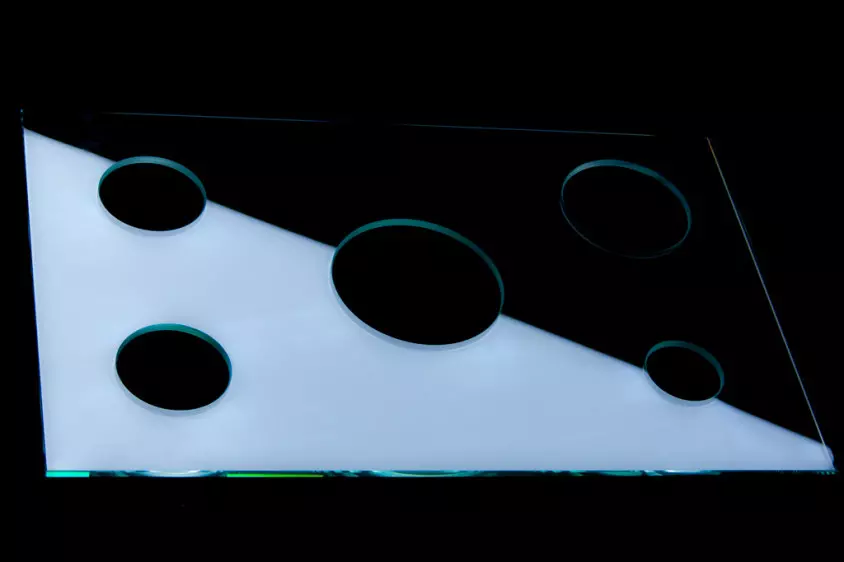

Drilling, milling and countersinking holes in glass and mirrors

Drilling of holes in glass, mirrors and triplex is carried out by our specialists on a special RBB di Brazzi machine.

Regular internal holes in glass, mirrors with a diameter of 40 mm or more, curved internal holes, triplex holes and the machining of internal hole edges are carried out on the Intermac Master 43 Glass+ multifunctional centre. Glass thickness can vary from 4 to 19 mm.